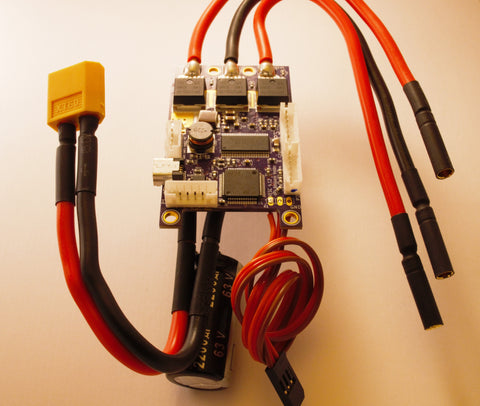

Vanda Electronics Speed Controller Motor Controller - Hardware Version 4.12 | Software Version 2.6 or later.

We recommend you purchase our Vanda Electronics Speed Controller with custom cables and connectors made just for your applications. You can pick your cable lengths and connectors and we will ship your VESC in 2 business days.

Minimum length 90mm!

The maximum length for cables is 300mm. If you enter a number larger than 300mm we will build your cables to 300mm.

If longer cables or different connectors are needed please email us.

Battery Connectors:

XT60 (male), Deans (male), EC3 (DEV/Male terminal), XT150 (Red=Female housing/Female Terminal Black=Male housing/Male Terminal, HXT4, XT90 (male) or 5.5mm (male) bullet

Motor Connector:

2mm female bullet, 3.5mm female bullet, 4mm female bullet, 5.5mm female bullet

PWM/Controller Connector:

Futaba ("male"=male housing/female terminals)

The most reliable and advanced open-source motor controller.

The hardware and software is open source. Since there are plenty of CPU-resources left, the customization possibilities are almost endless.

Features:

- STM32F4 microcontroller.

- DRV8302 MOSFET driver / buck converter / current shunt amplifier.

- IRFS7530 MOEFETs (other FETs in the same package also fit).

- 5V 1A output for external electronics from the buck converter integrated on the DRV8302.

- Voltage: 8V – 60V (Safe for 3S to 12S LiPo).

- Current: Up to 240A for a couple of seconds or about 50A continuous depending on the temperature and air circulation around the PCB.

- Sensored and sensorless FOC wich auto-detection of all motor parameters is implemented since FW 2.3.

- Firmware based on ChibiOS/RT.

- PCB size: slightly less than 40mm x 60mm.

- Current and voltage measurement on all phases.

- Regenerative braking.

- DC motors are also supported.

- Sensored or sensorless operation.

- A GUI with lots of configuration parameters

- Adaptive PWM frequency to get as good ADC measurements as possible.

- RPM-based phase advance (or timing/field weakening).

- Good start-up torque in the sensorless mode (and obviously in the sensored mode as well).

- The motor is used as a tachometer, which is good for odometry on modified RC cars.

- Duty-cycle control, speed control or current control.

- Seamless 4-quadrant operation.

- Interface to control the motor: PPM signal (RC servo), analog, UART, I2C, USB or CAN-bus.

- Wireless wii nunchuk (Nyko Kama) control through the I2C port. This is convenient for electric skateboards.

- Consumed and regenerated amp-hour and watt-hour counting.

- Optional PPM signal output. Useful when e.g. controlling an RC car from a raspberry pi or an android device.

- The USB port uses the modem profile, so an Android device can be connected to the motor controller without rooting. Because of the servo output, the odometry and the extra ADC inputs (that can be used for sensors), this is perfect for modifying an RC car to be controlled from Android (or raspberry pi).

- Adjustable protection against

- Low input voltage

- High input voltage

- High motor current

- High input current

- High regenerative braking current (separate limits for the motor and the input)

- Rapid duty cycle changes (ramping)

- High RPM (separate limits for each direction).

- When the current limits are hit, a soft back-off strategy is used while the motor keeps running. If the current becomes way too high, the motor is switched off completely.

- The RPM limit also has a soft back-off strategy.

- Commutation works perfectly even when the speed of the motor changes rapidly. This is due to the fact that the magnetic flux is integrated after the zero crossing instead of adding a delay based on the previous speed.

- When the motor is rotating while the controller is off, the commutations and the direction are tracked. The duty-cycle to get the same speed is also calculated. This is to get a smooth start when the motor is already spinning.

Sensored and sensorless FOC is fully implemented since FW 2.3.